View of Certainly Wood (from website referenced above)

Digital_Analog_Digital

Tracking the progress of research and investigation relative to spring 2017 sabbatical from Columbia College Chicago. Attempting to establish a dialog between digital ideation and fabrication AND manual or analog ideation and fabrication.

Thursday, October 5, 2017

Veneer received

Beautiful leaves arrived from Certainly Wood (East Aurora, NY), the best supplier of veneers to studio furniture makers (in my humble opinion) www.certainlywood.com

This photo shows raw veneer that is "wiped" with wet cloth to indicate (relative) appearance when finished (lower left section of veneer, which appears pinker, is dry). Depth of figure does not show, since this may very well be enhanced with colored dye prior to topcoat. The reflectivity is also not exactly apparent: higher gloss tends to enhance figure.

Thursday, September 28, 2017

Sample Development.2

Finally some sample development of intended veneer species. This is figured Movingue, also known as African Satinwood. This is a photo of a 12x18 sample, with clear satin finish. Also looking at producing gloss topcoat, to enhance the "depth" of the figure.

This is a closer view, showing the quarter-sliced grain, the mottled/curly figure, and the openness of the pores. Nature is striking!

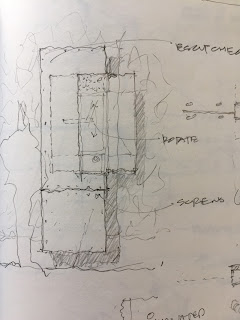

Below are sketches of the second piece underway. Colored image indicates location of this veneer. Alternating grain direction intended. Detailed sketches below. Seventh form the top indicates intention.

This is a closer view, showing the quarter-sliced grain, the mottled/curly figure, and the openness of the pores. Nature is striking!

Below are sketches of the second piece underway. Colored image indicates location of this veneer. Alternating grain direction intended. Detailed sketches below. Seventh form the top indicates intention.

Wednesday, August 23, 2017

Sample development

Finish samples. Durock with various coatings of oil, wax and raw.

Even with the sample in front of you, the variation

is surprisingly subtle. The line of the "waxed" area is

barely visible.

The top third of the sample in this photo shows the waxed

sheen a bit more. The haptic quality of the waxed area is

readily apparent when touching the surface. Since the

actual use/touching of the material is very important to me,

I'll end up waxing the surface.

Recovered Sketches_Lost + Wet

Below: a series of developmental and refinement sketches. Sketched from memory to replace lost sketchbook.

Thursday, August 10, 2017

Casting mockup + Panel finish sample development

Photos show mock up and finish samples of textured surface...and the material being investigated for the exterior of Entry Table #2 (actually much higher in sequence, but for these purposes it's 2).

The sheet is concrete board, typically used as underlayment for tile in water-prone areas. I've been interested in this panel due to its variations in surface, and the "mundane" quality; It would be unexpected in a piece of furniture. After considering it in sketches, my next step is to consider it's haptic qualities, and how it "works". In other words, can it be manipulated in a way that with satisfy functional and artistic ends.

Instead of the typical "score and crack" method, which for me leaves a very unsatisfactory edge, I attempted to cut an opening with a hand-held grinder with a fibrous cut-off wheel attached. This wheel is typically used for cutting ferrous metals, but worked well for this situation as well.

The scale and proportions are still a bit off (clunky),

but it's just a visual mock-up, right?

Rough edge, and cut edge

Detail of edge with finish applied.

Detail of face; left side is unfinished,

right has one coat of oil. I appreciate

how it emphasizes the color, and

especially the way it emphasizes

the underlying structural grid

Typically used as additive to oil paint

to assist with smoothness, but it is also

an excellent metal (steel) finish for exterior

settings. In this case, it's not bad for finishing

concrete board.

Maybe this will be the next natural object to

scan, manipulate, and print. Great texture.

Wednesday, May 31, 2017

Grant funding awarded

I am very thankful to the Faculty Development Grant Committee of Columbia College Chicago, who have awarded a FDG to support the fabrication of work developed and documented on this blog. Work to be completed between June and November of 2017.

Recent developmental work will be posted soon....traveling internationally for the next few weeks.

Recent developmental work will be posted soon....traveling internationally for the next few weeks.

Monday, March 13, 2017

Subscribe to:

Posts (Atom)